Physical and Mechanical Testing of Polymers

At ipolytech we are able to provide a wide range of mechanical/physical tests to allow a characterisation of the properties of thermoplastic, thermoset and elastomeric materials. Our test capabilities allow testing in all modes (tensile, compression, flexure) from sub ambient to elevated temperatures at speeds ranging from standard 1-500 mm/min to high speed tests up to 12 m/s.

Standard Physical and Mechanical Tests

Physical tests conducted include the determination of density or specific gravity of solid polymers, granules or foamed samples. Other physical properties determined include moisture absorption, Shore and IRHD hardness and colour.

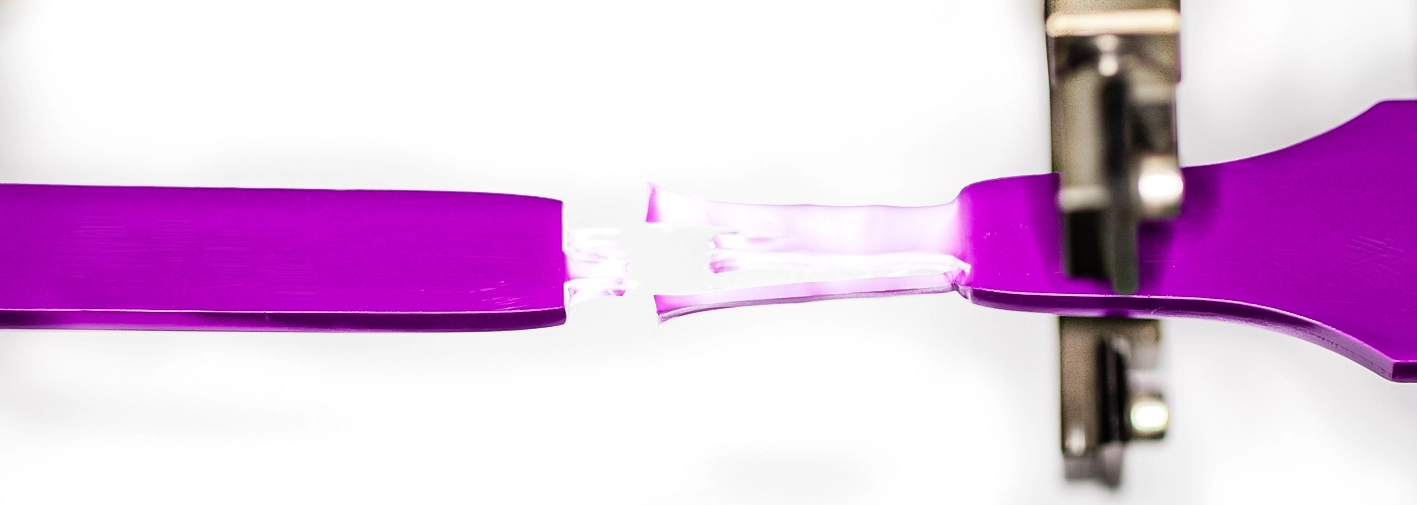

Standard mechanical tests are conducted to ISO or ASTM standard to determine the tensile, compressive, flexural and shear properties of a material over a wide range of test speeds and temperatures. Impact tests can also be conducted in Charpy, Izod or tensile impact modes.

High Speed Testing

As test speed increases the stiffness and strain acceptance of a polymer reduces. Appropriate mechanical test data is vital for modelling and simulation of high speed test data and can be achieved using our servo controlled test machine at speeds up to 12 m/s.

Tests are generally conducted in either tensile or dart penetration modes with extensions monitored using high speed video. With the liquid nitrogen cooled environmental chamber tests can be run at room temperature, elevated or sub-ambient temperatures.

Creep and Fatigue

Polymers are viscoelastic materials and their properties change with time under load. These can be either static loads (creep and stress relaxation) or variable/cyclic (fatigue).

The creep and fatigue resistance of materials can be assessed using a number of test techniques and loading modes to provide relevant long term design data for an application.

Chemical Resistance & Accelerated ageing

Chemical environments affect polymers through three major processes. When reliance on standard resistance datasheets if often insufficient to gain a true assessment of chemical resistance, we are experienced at defining and carrying out accelerated test programmes to determined the long term effects of chemicals on rubber and plastic materials under simulated service conditions.

Accelerated Ageing & UV Exposure

The term ageing generally applies to changes in material properties as a function of time. A number of different processes can take place and understanding these processes is key to determining the long term performance of a polymer product

Thermal Analysis

Thermal Analysis encompass a number of techniques used to characterise the changes in a polymer material as a function of temperature. At ipolytech we have a full suite of thermal analysis equipment including Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), Thermo-mechanical Analysis (TMA) and Dynamic Mechanical Analysis (DMA/DMTA)