Physical & Mechanical Testing of Plastics and Rubbers

Physical and mechanical tests are generally conducted to ISO specifications although ASTM and other test methods also be accommodated. Suitable test pieces can be obtained in house either from moulding from granules, or machining from sheet or suitably sized components. ipolytech's expertise comes into play in both defining mechanical test programmes to generate the data required and interpreting the data produced from a test programme to provide an informed assessment of the performance of the material under test.

The sections below give an overview of the common mechanical tests performed at ipolytech and gives an indication of our testing capabilities. Please contact us to discuss your specific requirements.

Physical Tests

Density/Specific Gravity

The density of plastic and rubber materials is performed in accordance with ISO 1183 and ISO 2781. The density of solid samples is determined in accordance with Method A of these standard - the water displacement technique. The material density and sample mass is often used to calculate sample volume and the volume change following immersion ageing. The density of powder or granular material is determined to Method B of ISO 1183 - the pycnometer method.

Water Absorption

A number of polymer materials and their additives are hydrophilic and will absorb moisture. Water absorption tests can be conducted to standard such as ISO 62 testing in air humid air or by water immersion to determine the percentage uptake either in a 24 hour period of to saturation. Immersion tests can be in distilled water, tap water or simulated sea water as applicable.

Surface Hardness

Surface hardness can be measured on both Shore A and Shore D scales as well as IRHD. To test to relevant standards for these methods a flat sample of 4-6 mm thickness is generally required. For thinner samples, plying of up to three layers is generally acceptable. As an alternative the apparent IRHD can be determined using a micro IRHD meter. Testing is conducted in accordance with ISO 48, ISO 868, ISO 7619 or ASTM D2240

Mechanical Tests

Impact Testing

Charpy and Izod impact tests are conducted to ISO 179 and ISO 180 respectively. In both tests the preferred samples dimensions are a beam 80 mm x 10 mm x 4 mm although other dimensions can be accommodated. Tensile Impact test are conducted to ISO 8256 Method A (stationary sample). All impact tests can be conducted either un-notched or notched with a Type A or Type B notch.

Flexural Modulus and Strength

Flexural tests are conducted in accordance with ISO 178. The preferred test piece geometry is a sample 80 mm x 10 mm x 4 mm which is tested in three point bending with a span of 64 mm. This test piece geometry can either be machined or taken from the central section of on injection moulded test sample. Testing is conducted to a maximum of 5% strain to determine the flexural modulus, and any yield properties. If failure does not occur within 5% strain a "stress at conventional deformation" is quoted.

Tensile Properties - Plastics

The tensile properties of plastic materials are determined in accordance with ISO 527 or ASTM D638. Tests can be conducted on a range of test machine/load cell configurations up to 100 kN with strain measurement either by long range contacting or non-contacting video extensometry systems. Testing determines the tensile modulus, yield and failure properties of the polymer and can be run from sub-ambient to elevated temperatures.

The property used to determine the "tensile strength" of a plastic material depends on the response of the polymers, in materials showing yield the strength is taken as the yield point, for non-yielding or brittle materials the strength can be defined as either the maximum stress or the stress at break.

The Poisson's ratio can also be obtained during the test by determining the strain response in two perpendicular directions. Test speeds of 1 mm/min are used for modulus determinations whilst other properties are typically determined at speeds between 1 mm/min and 500 mm/min dependent on the material. Going beyond the bounds of ISO 527 our high speed test capabilities allow tests up to 12 m/s.

Tensile Properties - Elastomers

The tensile properties of rubbers/elastomers and determined in accordance with ISO 37 or ASTM D412. Tests are generally conduced at relative high extension rates around 500 mm/minute.

Data typically generated during the test includes the stress at predefined extension (such as 10%, 50% strain) together with the ultimate tensile strength (UTS) and elongation at failure. Yield properties can also be obtained if appropriate.

The Poisson's ratio can also be obtained during the test by determining the strain response in two perpendicular directions. Alternatively, the Poisson's ratio of an elastomer can be determined from bulk modulus tests which often provides a better parameter for use in FEA models.

When tested at room temperature we have the capability of testing to high strains in excess of 1000% with extensions monitored by either no-contacting video extensometers or long range contacting extensometers.

Compressive Properties - Plastics

The compressive properties of plastic materials are determined in accordance with ISO 604. The preferred samples for compressive modulus determinations are 50 x 10 x 4 mm and for compressive strength tests 10 x 10 x 4 mm. Tests speed are 1 mm/min for modulus determinations and brittle materials and 5 mm/min for compressive strength determination of yielding materials. Our test machines have the capabilities of test at loads up to 100 kN with strains monitored either by cross head encoders or a non-contacting video extensometry system.

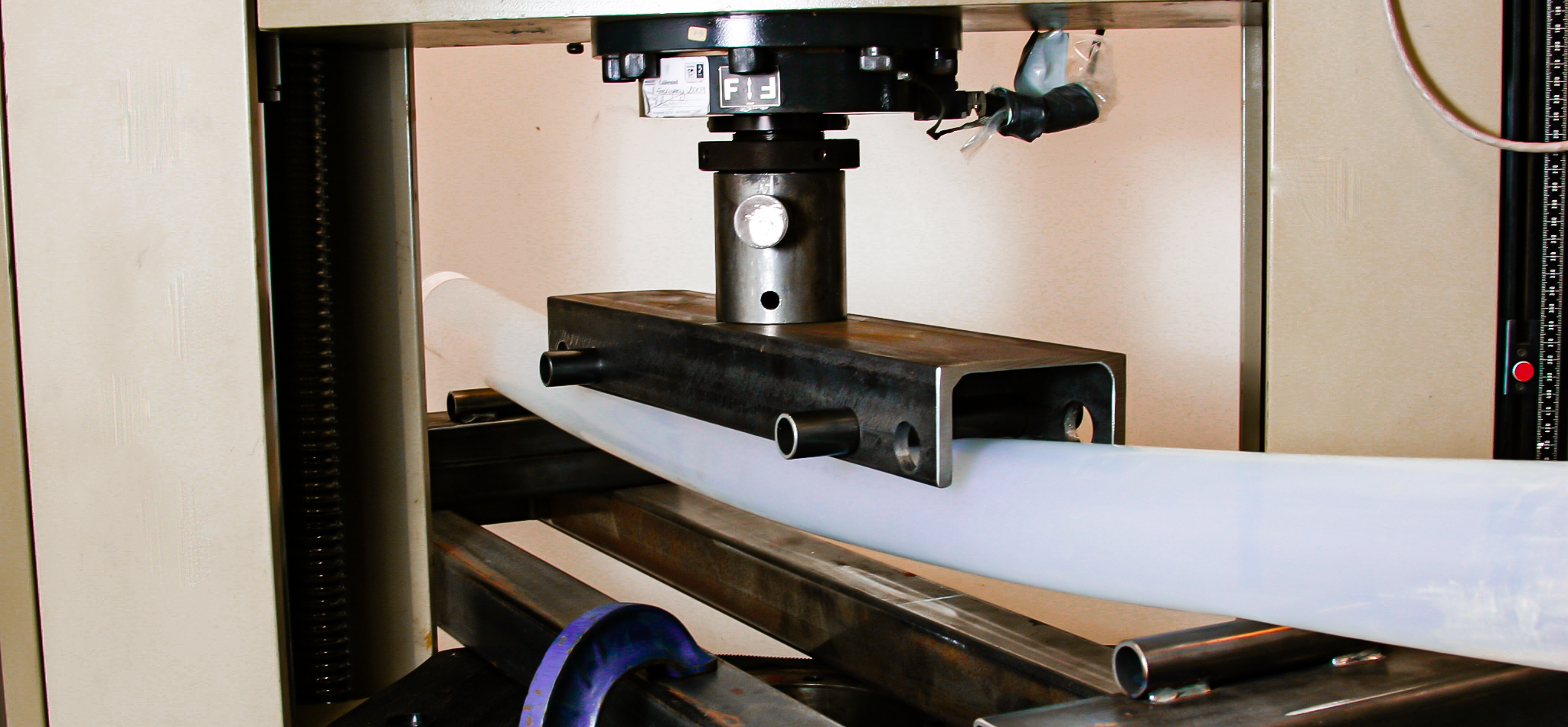

Compressive Testing - Elastomers

The stress vs strain characteristics when compressing an elastomer are strongly affected by the shape factor which is the ratio of the loaded area to the force free area. ASTM D575 uses a specimen 12.5 ± 0.5mm thick and diameter 28.804mm. There is no equivalent ISO standard. Due to the affect of shape factor on the apparent modulus, it is often better to test the actual component in compression and ipolytech can perform test up to a force of 100kN.

Compression Set

Compression set testing is generally performed to ISO 815. The standard uses two different sizes of specimen, designated type A and type B which do not necessarily give comparable data. The type A specimen is a disc of diameter 29 mm ± 0,5 mm and thickness 12.5 mm ± 0.5 mm, and is usually preferred for testing elastomers of low compression set. The type B specimen is a disc of diameter 13 mm ± 0,5 mm and thickness 6.3 mm ± 0.3 mm and is often used when machining specimens from products. The test involves compressing the specimen by a known strain and then holding the compressed sample at the test temperature for a defined period of time before releasing the strain and measuring the specimen height after recovery. The compression set is expressed as a percentage of the initial compression.

Elastomer Tear

Tests are performed to ISO34 using trouser tear, crescent tear (nicked), nicked or un-nicked angle tear methods. The tearing force is measured and is dependent not only on the material, but on the test piece geometry selected and the form of the discontinuity (nick, cut, angle etc). Hence, the tear strength should not be thought of as a fundamental property of the material and it is difficult to directly correlate with service performance. However, it has significant benefits when used as a comparative test or as a quality control test; so long as the factors affecting the results are understood and considered. Tests can also be performed to selected sections of ASTM D624.

Shear Properties

The shear properties of a material can be determined using a number of standard methods. The shear strength can be determined in accordance with ASTM D732 which determines the forces to shear a 1 inch diameter die through a clamped sample. The shear strength and modulus of cellular/foamed materials can be determined in accordance with ISO 1922 of ISO 12090 by bonding the sample to steel shear plates.

Hyperelastic Material Characterisation

Elastomeric materials are generally incompressible non-linear elastic materials whose stress strain response can be defined by a number of hyperelastic material models. Calibration of these material models for use in finite element stress analysis (FEA) requires the material to be loaded in a number of different loading modes. We are able to test rubber materials in uniaxial tension & compression, volumetric compression, planar tension (pure shear) and biaxial tension to provide suitable materials data for definition of a number of hyperelastic material models.

Puncture Resistance

Puncture Resistance The puncture resistance of flexible packaging materials and films are determined in accordance with EN14477. In this test a 0.8 mm diameter tip is driven through a film samples and the peak force to penetrate the film recorded.Testing can be conducted at a range of speeds between 1 and 100 mm/min.

Non-standard & Product Testing

Using the knowledge of standard test methods, in conjunction with our experience of the potential failure modes of polymer products, ipolytech are able to advise on the development and use of non-standard tests applied to components and finished products. This allows complex failure modes to be assessed and weaknesses in design or production to be identified.